Electric Water Pump EPH2500H-00

Classification:

Technical data

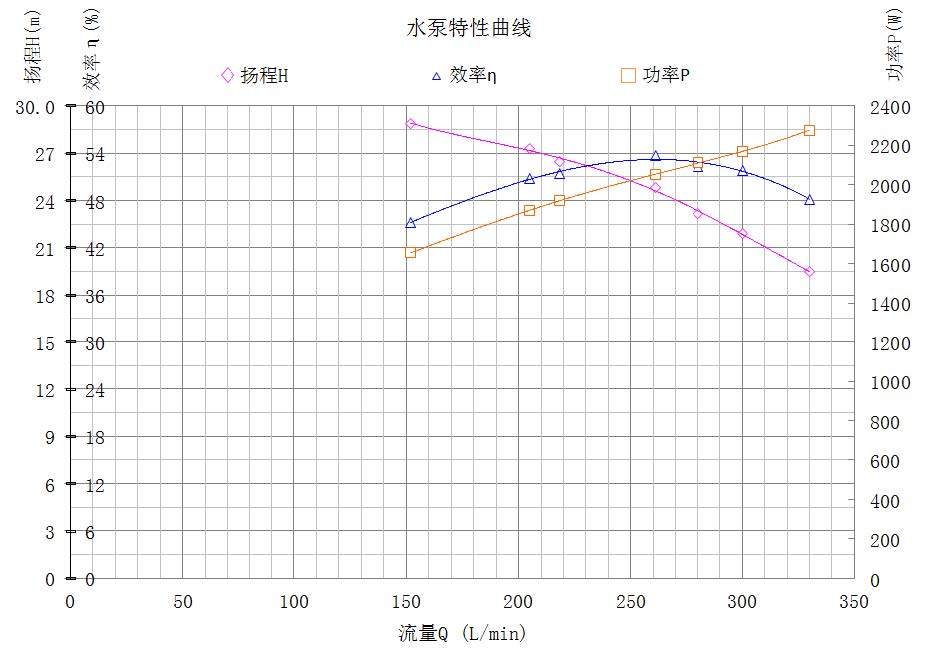

| Model | EPH2500H-00 |

| Rated Flow and Head | 260L/min@24m |

| Rated Power | 2500W |

| Rated Voltage | 545V DC |

| Max. head | 330L/min |

| Max. flow | 30m |

| Noise | ≤70dB(A) @ 1m |

| Communication | CAN2.0B |

Product Details

- Description

- Product Advantages

- Technical Data

-

- Commodity name: Electric Water Pump EPH2500H-00

- Commodity ID: EPH2500H-00

<br><table align="center" border="1" cellpadding="0" cellspacing="0" style="width:100%;"> <tbody> <tr> <td><strong>Model</strong></td> <td>EPH2500H-00</td> </tr> <tr> <td><strong>Rated Flow and Head</strong></td> <td>260L/min@24m</td> </tr> <tr> <td><strong>Rated Power</strong> </td> <td>2500W</td> </tr> <tr> <td><strong>Rated Voltage </strong></td> <td>545V DC</td> </tr> <tr> <td><strong>Max. head</strong></td> <td>330L/min</td> </tr> <tr> <td><strong>Max. flow</strong></td> <td>30m</td> </tr> <tr> <td><strong>Noise</strong></td> <td>≤70dB(A) @ 1m </td> </tr> <tr> <td><strong>Communication</strong></td> <td>CAN2.0B</td> </tr> </tbody> </table>

Model EPH2500H-00 Rated Flow and Head 260L/min@24m Rated Power 2500W Rated Voltage 545V DC Max. head 330L/min Max. flow 30m Noise ≤70dB(A) @ 1m Communication CAN2.0B

The electric water pump for hydrogen fuel cells plays a critical role in ensuring the efficient operation of hydrogen-powered systems. Hydrogen fuel cells are rapidly becoming a popular alternative energy source due to their environmentally friendly and efficient performance. The water pump, as part of the overall fuel cell system, manages the circulation of water, maintaining optimal temperature and pressure levels within the fuel cell stack.

Hydrogen fuel cells generate electricity by combining hydrogen and oxygen in an electrochemical reaction, a process that produces water as a byproduct. The water produced can accumulate within the system, and without proper management, it could lead to operational inefficiencies. This is where the electric water pump comes into play. By continuously circulating water through the fuel cell stack, the pump ensures that the system remains hydrated and can effectively dissipate the heat generated during the electrochemical reaction.

One of the most important features of an electric water pump for hydrogen fuel cells is its ability to maintain a stable flow of water under varying temperatures and pressures. Since the hydrogen fuel cell operates under high-temperature conditions, the pump must be designed to withstand extreme heat and pressure while providing reliable performance. This requires a durable motor and high-quality materials that can resist corrosion, especially because the water used in the system can be slightly acidic due to the production of hydrogen ions during operation.

Another key factor to consider when choosing an electric water pump for a hydrogen fuel cell is energy efficiency. Since hydrogen fuel cells are designed to operate efficiently, it is crucial that the water pump also operates with minimal energy consumption. The electric motor used in the pump must be optimized to minimize power consumption without compromising performance. This contributes to the overall energy efficiency of the entire hydrogen fuel cell system, ensuring that as much energy as possible is directed toward electricity production rather than wasted on auxiliary components like the water pump.

Finally, reliability and longevity are critical considerations for an electric water pump in a hydrogen fuel cell system. Given the high demand for continuous operation, the pump must be capable of delivering consistent performance over an extended period. Frequent maintenance or replacement could undermine the system's efficiency and increase operational costs, so manufacturers often design these pumps with long-lasting components and low maintenance requirements.

-

Electric Water Pump applied to Hydrogen fuel engine system/energy storage battery thermal management liquid cooling system.

1.Shielding structure, low noise, high stability, long life;

2.Dielectric insulation;

3.High voltage water pump control;

4.Permanent magnet synchronous motor, high efficiency.

-

key word:

coolant pump

auto electric water pump

electric coolant pump

Electric Water Pump for Engine Cooling

automotive electric water pump

Electric coolant pump

Electric Water Pump for Hydrogen fuel cell

| Model | EPH2500H-00 |

| Rated Flow and Head | 260L/min@24m |

| Rated Power | 2500W |

| Rated Voltage | 545V DC |

| Max. head | 330L/min |

| Max. flow | 30m |

| Noise | ≤70dB(A) @ 1m |

| Communication | CAN2.0B |

The electric water pump for hydrogen fuel cells plays a critical role in ensuring the efficient operation of hydrogen-powered systems. Hydrogen fuel cells are rapidly becoming a popular alternative energy source due to their environmentally friendly and efficient performance. The water pump, as part of the overall fuel cell system, manages the circulation of water, maintaining optimal temperature and pressure levels within the fuel cell stack.

Hydrogen fuel cells generate electricity by combining hydrogen and oxygen in an electrochemical reaction, a process that produces water as a byproduct. The water produced can accumulate within the system, and without proper management, it could lead to operational inefficiencies. This is where the electric water pump comes into play. By continuously circulating water through the fuel cell stack, the pump ensures that the system remains hydrated and can effectively dissipate the heat generated during the electrochemical reaction.

One of the most important features of an electric water pump for hydrogen fuel cells is its ability to maintain a stable flow of water under varying temperatures and pressures. Since the hydrogen fuel cell operates under high-temperature conditions, the pump must be designed to withstand extreme heat and pressure while providing reliable performance. This requires a durable motor and high-quality materials that can resist corrosion, especially because the water used in the system can be slightly acidic due to the production of hydrogen ions during operation.

Another key factor to consider when choosing an electric water pump for a hydrogen fuel cell is energy efficiency. Since hydrogen fuel cells are designed to operate efficiently, it is crucial that the water pump also operates with minimal energy consumption. The electric motor used in the pump must be optimized to minimize power consumption without compromising performance. This contributes to the overall energy efficiency of the entire hydrogen fuel cell system, ensuring that as much energy as possible is directed toward electricity production rather than wasted on auxiliary components like the water pump.

Finally, reliability and longevity are critical considerations for an electric water pump in a hydrogen fuel cell system. Given the high demand for continuous operation, the pump must be capable of delivering consistent performance over an extended period. Frequent maintenance or replacement could undermine the system's efficiency and increase operational costs, so manufacturers often design these pumps with long-lasting components and low maintenance requirements.

Related Products

Product inquiry